Data Centers normally have huge energy consumption demands. Extensive research is being devoted to reducing the energy footprint of Data Centers worldwide, with innovations such as industrial roller shutter doors playing a significant role. If you’re interested in sustainable initiatives like these, you might also want to explore options such as UK Government Grants for House Repairs. For optimizing energy efficiency in infrastructure projects, consider consulting with experienced structural glazing contractors who can contribute to sustainable building practices. It is also advised to schedule an air conditioning repair service at least once a year to maintain the efficiency of your hvac system.

As a result of the research done in integrating electronic controls and humidification technologies for this application, CAREL has developed a new, high efficient solution for part of the overall energy demand.

This technology is the new evaporative cooling system called optiMist.

This new product works both as an evaporative cooler and a humidifier. That means a single product inside the air conditioning unit serves two functions. The evaporative cooling produced by the optiMist reduces the air conditioning cooling load and refrigeration compressor run time.

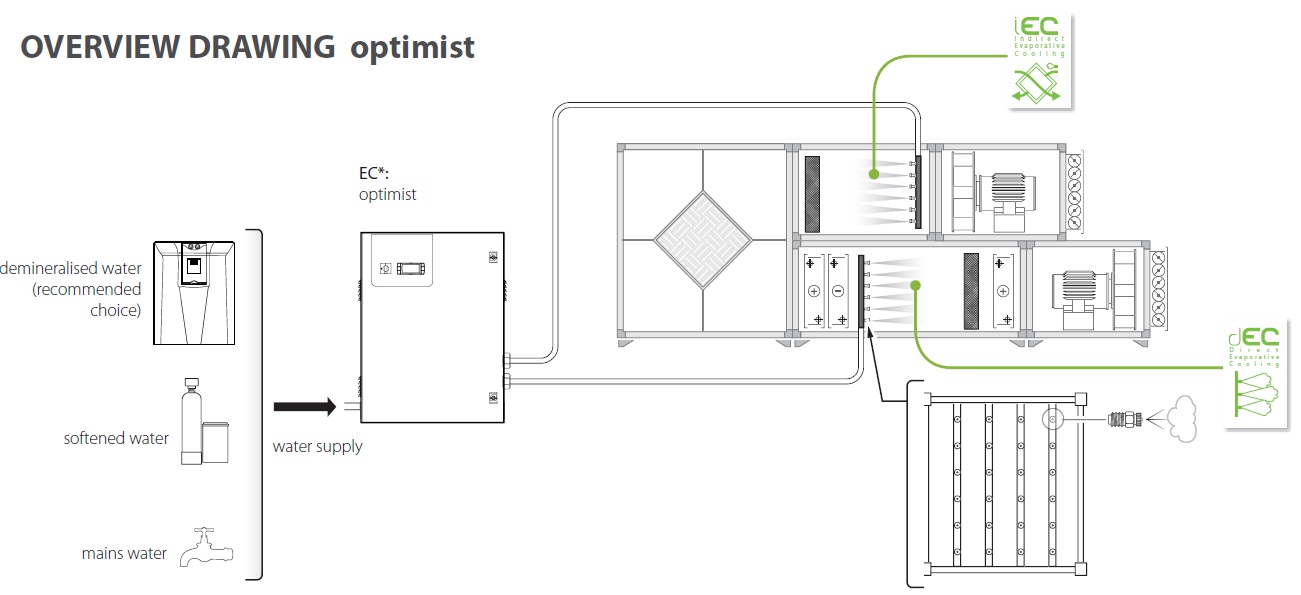

The optiMist is installed in the AHU with humidification distribution in the humidification compartment AND in the exhaust air flow (upstream of the heat exchanger) of the Data Center air conditioning units. When ac short cycling, call an HVAC professional as soon as you spot the problem.

It receives two separate signals, one relating to humidification (winter) and one for evaporative cooling (summer), producing a flow of atomized water inside the AHU during both seasons. The use of composite flooring systems in the Data Center can further enhance efficiency by providing a durable surface that supports optimal performance of the HVAC system. In addition, ensuring proper commercial lighting in these facilities plays a key role in maintaining overall system functionality and safety.

The optiMist summer/winter feature includes a water inlet circuit, a volumetric pump and two solenoid valves to distribute atomized water at 232 psi (16 bars). Inside the CAREL electrical panel is the power circuit, a programmable electronic controller and an inverter. Additionally, for the safety and compliance of the systems, it is essential to seek advice from a professional for EICR testing. For more information, you can also check out this resource at electricaltestingreport.co.uk.

The optiMist receives the control signal from a remote control device or directly from temperature and humidity probes. The electronic controller calculates the flow-rate of atomized water required to meet the evaporative cooling or humidity demand and signals the required pump speed to the inverter. This avoids waste by ensuring linear modulation of atomized water producing precise temperature and relative humidity control.

Evaporative cooling occurs due to the spontaneous evaporation of atomized water droplets that are introduced upstream of the cooling coil. This change in phase from liquid to vapor extracts heat (energy) from the air. Evaporation of 220 lbs/hr (100 kg/h) of water absorbs 235,438 btuh (69 kW) of heat from the air. Depending on the air flow rate the return air can be cooled by several degrees inside the air conditioner before being discharged into the Data Center. This cooling capacity can be exploited to cool the fresh inlet air by using a heat exchanger, with an efficiency – depending on the heat recovery unit – that may exceed 50%! This means the size, capacity and power consumption of the cooling coil and chiller can be reduced and still meet the load requirement of the Data Center.

Special care has been paid to hygiene when designing the optiMist for Legionella bacteria prevention. Hygiene concerns have been an chronic problem with ultrasonic-style humidifiers that are used by some Data Center air conditioner manufacturers.

The built-in CAREL pCO sistema+ controller automatically:

• Fills the lines only when humidification or evaporative cooling are required

• Empties the lines when there is no humidification or evaporative cooling demand for some time

• Periodically washes the lines

The washing cycle is performed using dedicated solenoid valves, and not by spraying the water being drained.

CAREL offers the following energy efficient, innovative features with this new product:

1. optiMist guarantees considerable energy savings year-round by providing evaporative cooling in summer and precise humidification control in winter.

2. Unlike evaporative coolers/humidifiers that use wet deck technology, optiMist does not create additional pressure drop for the fans on the air handling unit.

3. optiMist can receive a limit signal directly from the exhaust air fan or from the re-circulation damper actuator. This innovation optimizes evaporative cooling by ensuring water is not wasted.

4. Compared to existing systems on the market that use the wetted media technology, optiMist optimizes pump operation using an inverter, meaning no energy is wasted.

Another energy saving option is a special inverter that can control the atomizer pump with permanent magnet brushless motors (BLDC/BLAC) called power+.

Modulating the pump speed and the capacity of the refrigeration unit by integrating a CAREL pCO sistema+, produces significant energy savings. Variations in the cooling loads are managed precisely and with constant control of the compressor envelope.

This produces significant increases in the unit’s refrigeration cycle COP (Coefficient Of Performance) during operation at part load, giving higher summer cooling operational savings.

Other advantages obtainable with DC inverter technology include:

• More precise control of water temperature even in response to peaks in demand, reducing or avoiding the use of water storage tanks.

• Working at part load, the heat exchangers become more efficient and the unit can work at higher suction pressure and lower condensing pressure.

• The outdoor coil ices up less, reducing the need for defrosts on air and water source heat pumps.

Some of the main features include:

• Sensorless motor control technology

• Custom acceleration ramp

• Wide operating range, up to 140°F (60°C) ambient

• Low noise due to the high switching frequency, up to 8 kHz

• Safety torque off input

The optiMist control can easily be installed in electrical panels thanks to the gasket and smart bracket system. The heat sink can be located in the condenser compartment.

Complete integration of the pCO sistema+ means:

• Envelope control

• Integrated electronic thermal expansion valve management

• Quick inverter setup using a preloaded table of parameters based on compressor type

Carel has completed projects for Data Centers in the USA and Europe. They have also partnered with most of the important Data Center temperature control players in the market.

For further information contact:

Laura Galvani

Corporate Communications Manager

laura.galvani@carel.com

direct +39 049 9716 785

CAREL INDUSTRIES S.p.A. (Headquarters)

Via dell’Industria 11

35020 Brugine (Padua) – Italy

phone +39 049 9716 611

fax +39 049 9716 600